Production Planning and Detailed Scheduling

The fastest way from raw material to product

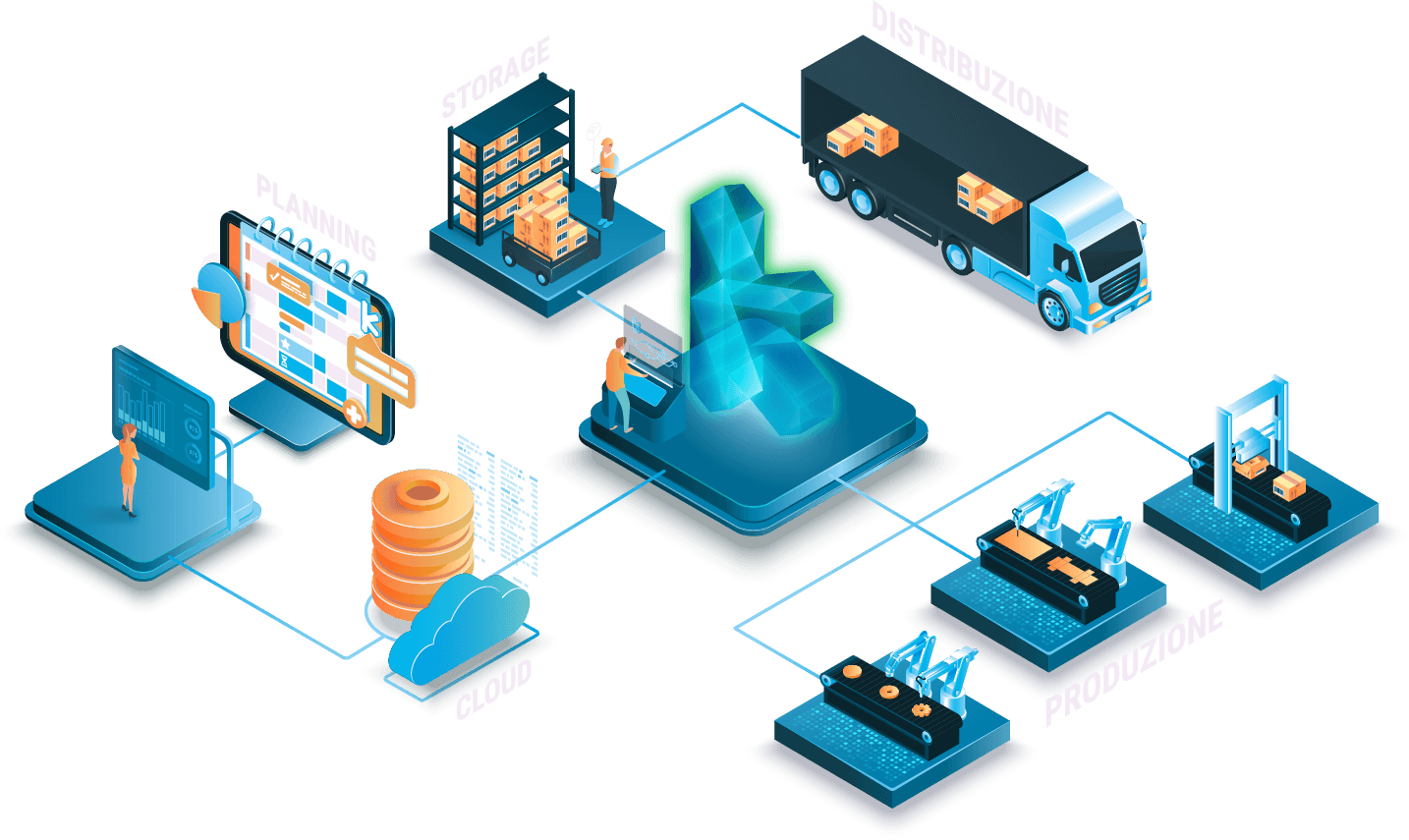

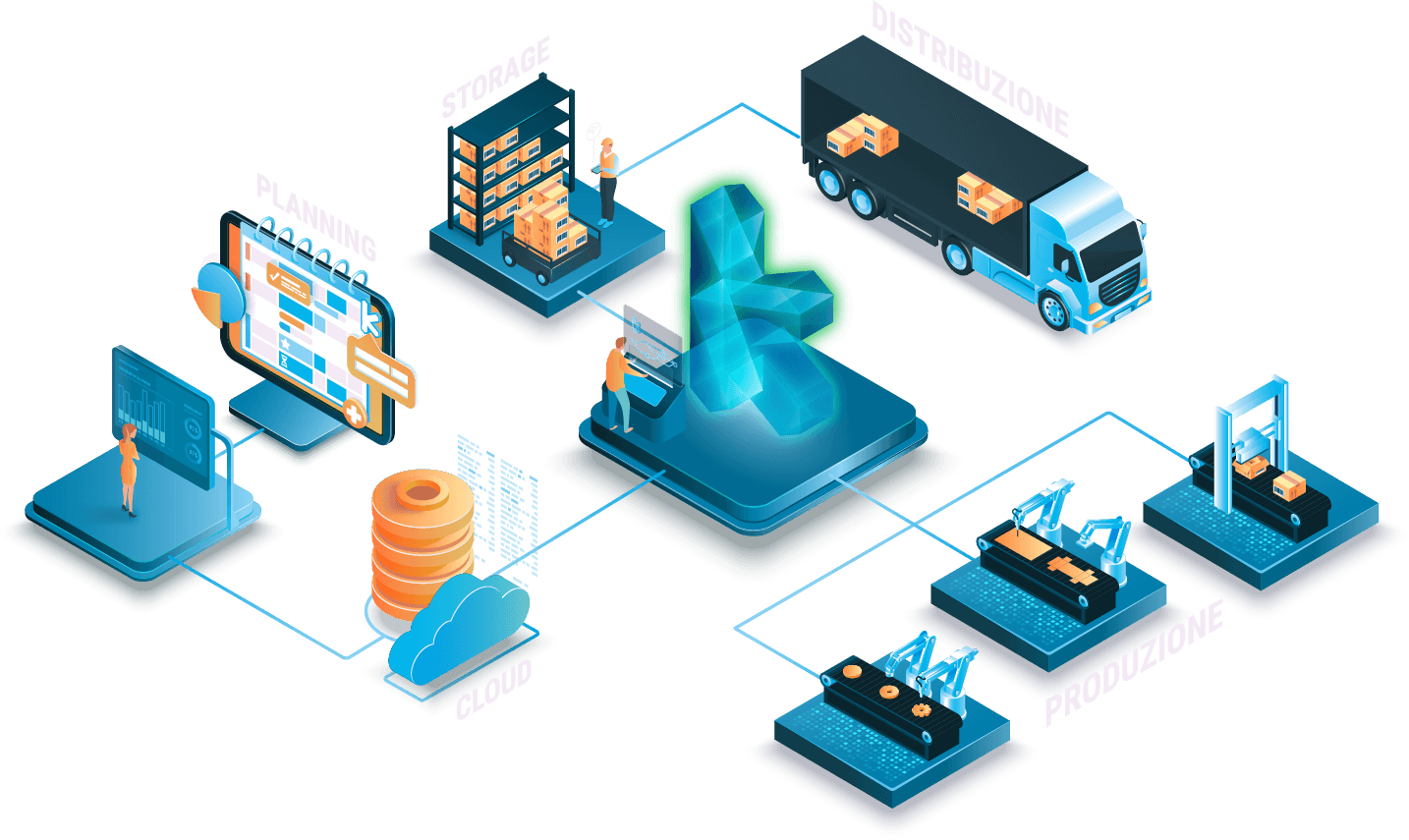

Tutte i piani di produzione portano al prodotto finito, ma alcuni ci arrivano prima e meglio. Kimeme PPDS è il tool per l’industria 4.0 che analizza la tua supply chain, simula gli scenari possibili e ti fornisce i consigli giusti per migliorare l’efficienza del tuo impianto.

Kimeme interviene su tutti gli aspetti della catena di produzione: progettazione, realizzazione, approvvigionamento, gestione scorte, logistica e manutenzione. Non sostituisce l’Head of Production, ma è un supporto decisionale indispensabile per l’analisi dei processi e l’ottimizzazione degli impianti.

We have a plan: yours

Kimeme PPDS analizza a fondo la catena di produzione per individuare sprechi, tempi morti, sovraccarichi di risorse. Analizza i livelli di stock in base all’andamento degli ordini e alle previsioni della domanda, simula gli scenari futuri e crea per te il miglior piano di produzione possibile.

Personalizza Kimeme PPDS tarandolo sulle tue necessità, i tuoi vincoli e obiettivi, e lui farà il resto. Ti aiuterà a definire non solo cosa produrre e in che quantità, ma anche su che macchina, con che personale e in quanto tempo.

Produce more, save more

With Kimeme PPDS all your production goals have never been so close. The software releases a plan optimized according to your needs, reducing the lead time and increasing competitiveness without increasing the invested resources. Promptly responsive service with a better responsiveness to problems, reduction of waiting times, more rapid deliveries and efficient personnel without overloads and higher cash flow: isn’t it the company of your dreams?

The future is data-driven

Kimeme PPDS always knows in every link of your production chain: thanks to its light and fast user-friendly interface, Kimeme PPDS keeps information centralized and shared, receiving and making accessible the right data, from the right persons, to the right moment.

The on-cloud platform connects with your machines to acquire and analyse data simultaneously from all the company departments, releasing integrated production plans which facilitate the cooperation among purchase, production and commercial.

What you can do with Kimeme PPDS:

- Collection and on-cloud analysis of data of the whole production chain

- Multi-based level distinguished management, capacity of finished production, make-to-stock and just-in-time (JIT) mode.

- Simulation of alternative scenarios to your present production plan

- Real-time design of scheduling plans and optimized production optimized according to user-based obligations

- Optimized machining sequences for individual machine, respecting priorities, obligations, deliveries

- Mapping of obligations and delivery of each line of production

- Integration with ERP and company software (sap, MS Navision etc.)

- Integration with the main MES (Manufacturing Execution System) systems, to implement the paradigm I4.0 using in real time the production data in order to reschedule in real time (RT Scheduling)

- Optimization of the lead time, reduction of delivery times of the finished product

- Completely customizable obligations

- Increase of the flow efficiency

It’s the right tool for those who need to:

Optimize the production chain

Manage complex plants, involving several departments

Increase the production volumes without expanding the existing plants

Manage medium-big volumes of products, following the most different steps, from the supply of raw materials to the stocking and retails

Reduce the lead time simplifying the production chain

Manage the PDCA cycle managing the incidence of unexpected events

Technical specifications

Watch the video

Case study

A multinational specialized in the supply of high-technology products and systems for automotive industry has requested the use of Kimeme PPDS to reduce the volume of pending orders. The final goal was to increase the revenues for the same production capacity, optimizing costs with an efficient planning of the warehouse stocks.

- Analisi dell’impianto e della turnazione della forza lavoro

- Razionalizzazione degli ordini

- Applicazione di nuovi vincoli di pianificazione su una singola linea e valutazione del risultato da applicare al processo

- Ottimizzazione del piano di produzione

- Ridimensionamento dello scheduling

- Reduction of not processed orders, with recovery of missing revenues equal to +8% towards the standard plan

- Reduction of the general machine and line setup times, managing the availability of the technical personnel

- Reduction of 60% of items in the warehouse

Plans and licenses

Kimeme PPDS is available with license SAAS and on premise,

tailored on your needs, according to the operators to manage and to the number of plants you need.

Ask for a call with a CyberDyne advisor

to analyse together the most suitable license for your company.

SAAS

No problems with compatibility, hardware upgrade, data storage processing speed: with the SaaS license, Kimeme is quickly operational. The technical support CyberDyne accompanies you in its first setup and remains at your disposal for troubleshooting.

On Premise

The on premise license id recommended in case you want to use Kimeme to manage particularly sensitive data. The processing and storage of data are completely performed on your hardware, without external interchanges on the network. The CyberDyne team will assess with you the minimum requisites needed and will support you step by step on the setup and the use.

Proof of Concept

You are not sure Kimeme PPDS can meet your needs? You can ask for a Proof of Concept with a team just for you. We’ll test Kimeme WFM directly on your company, working on a part of the plant limited but sufficiently complex.